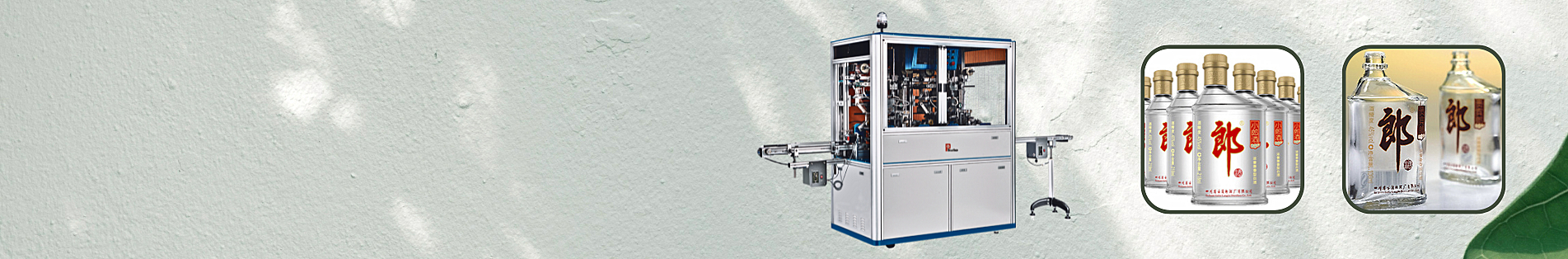

Semi Automatic Water Cup Heat Transfer Machine

Application

This heat transfer machine is widely applied for printing on conical water cup and other cone shape products.

Products to print: water bottle, water glass, drinking cups, cone cups, wine bottle, mug, glass bottle, milk cup, cosmetic bottle etc.

Description

Reviews

Description

1. PLC control system, easy to set data, the machine can automatically calculate working trail once input three parameters, which are the perimeter of top and bottom, bucket, and height of the bucket.

2. The air pressure sensor makes the machine more balanced.

3. Heat transfer pressure, temperature, speed, and time of transfer are adjustable.

4. Adjusting with different angles and front-back positions on bottom of mold.

5. The tension control system makes the transfer film smooth, not folded.

6. Precise sensor combines with two times speed up to collect the foil.

7. The pattern of heat transfer is stable enough, especially suitable for something precise.

8. XYZ triaxial servo matches taper and working trail which enables the photo to be transferred in a highly accurate position.

9. This is a patent machine with patent number: ZL201620065617.6

Parameters

| Max. size of product: | H200*Φ220mm |

| Speed of transfer: | 300-400pcs/h |

| Timing of transfer: | 4seconds/pc |

| Air consumption: | 0.6-0.8mpa |

| Power supply: | 220v 50hz 3.8kw 28a |

| Dimension: | 1600*1200*1800mm |

| Weight | 680kgs |

Printed samples

For more operating video of our machine please visit YouTube from below link

Package & Delivery

Every machine is under standard package standard.

Machine vacuumed if necessary and packed into fumigation free wooden package.

Package delivered to seaport/airport by direct line truck.

For more questions and details please ask us directly, we will reply you ASAP.