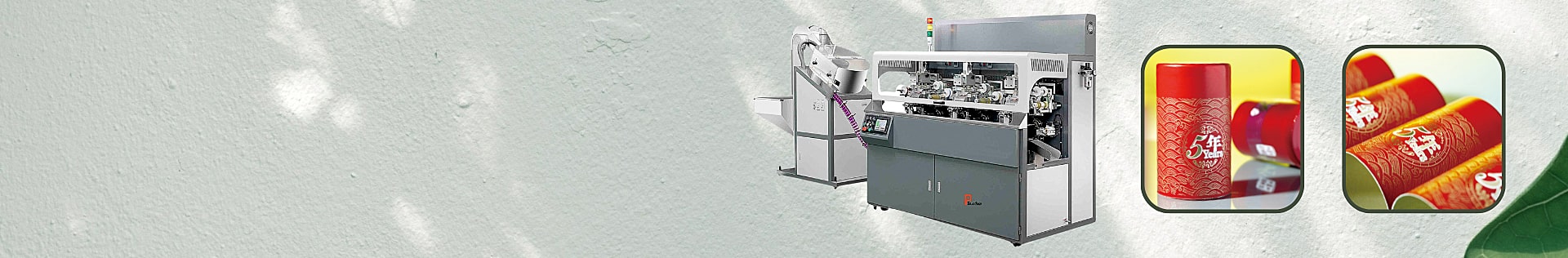

Bottle Cap Screen Printing and Hot Stamping Machine

Application

This high-speed automatic multifunctional machine combines a hot stamping station with a screen printing station for its multipurpose application. According to the customer’s need, equipment can be made with one screen printing station and two hot stamping stations, or two screen printing stations and one hot stamping station. It is used for printing bottle caps, tubes small bottles etc. Products to print: plastic bottle caps, aluminum caps, glass bottle caps, bottle tops, recycle bottle caps, bottle closures, vinyl end caps, lipstick tubes, lipstick containers, glass vials, wine caps, wine closures, etc.

Description

Reviews

Description

1. Operation through PLC and touch screen display.

2. Auto-loading system, feeding and cap unloading device.

3. Flame treatment device.

4. “No item no print/stamp” warning system.

5. Cap counting device additionally if needed.

6. Tooling parts replace for another size of work pieces (if needed).

Parameters

| Speed of stamping: | 3000-3600pcs/h |

| Size of stamping: |

Max. diameter Φ15-34mm Max. length Φ25-60mm Max. bottle diameter Φ20-65mm Max. bottle length Φ25-150mm |

| Air consumption: | 0.6-0.8mpa |

| Power supply: | 380v 50hz |

| Dimension | 2300*1400*2300mm |

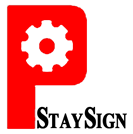

Printed samples

For more operating video of our machine please visit YouTube from below link

Package & Delivery

Every machine is under standard package standard.

Machine vacuumed if necessary and packed into fumigation free wooden package.

Package delivered to seaport/airport by direct line truck.

For more questions and details please ask us directly, we will reply you ASAP.